The testo 350 Portable Emission Analyzer

Whether you are testing for compliance or troubleshooting and tuning the testo 350 portable emission analyzer offers everything you need!

Control Unit - for remote control operation

- Color graphic display is easy to see in dark or bright conditions

- Go wireless with long-range 300 ft. Bluetooth (or wired to over 3,000 ft.) to eliminate long sample lines

- Hands-free operation with integrated magnets for mounting to steel surfaces

Analyzer box - for high accuracy measurements

- Contains up to six sensors, pumps, gas path, sample conditioning, and more

- Utilizes continuous sensor temperature monitoring for superior accuracy

- Conditions the gas sample automatically, thermoelectric (peltier) chiller as required by regulatory agencies

A wide selection of probes for every application

Built for superior job site performance

The testo 350 represents the latest in portable emission analyzer technology for longer up-time in the field and lower cost of ownership.

1. CONTROL UNIT – SMALL AND CONVENIENT

The control unit is the operating and display unit of the testo 350. It can be removed and equipped as standard with a Li-ion rechareable battery. All settings are carried out using the cursor button. The presentation of the measurement values takes place via the colour graphic display. Thanks to the internal memory, measurement data can be transferred from the analyzer box to the control unit. If required by the measurement, several analyzer boxes can conveniently be operated and controlled using one control unit

The advantages of the testo 350 control unit:

- Operation of the analyzer box and transfer of the measurement data even when the flue gas pipe and the adjustment site are separated, especiall helpful for industrial burners, for example.

- Measurement data can be transferred from the analyzer box to the control unit. This means the analyzer box can remain at the measurement site for further measurements, and the control unit taken away in order to process the measurement data.

- In order to protect the display in measurements over a longer period or during transport to different measurement sites in a system, the control unit can be attached to the analyzer box face-down.

2. LARGE COLOUR GRAPHIC DISPLAY WITH APPLICATION-SPECIFIC MENU

The advantages of the application-specific menu

- Information in the display guides the user through the menu.

- Easy operation without previous knowledge of the instrument

- Reduction of the work steps before the start of the measurement

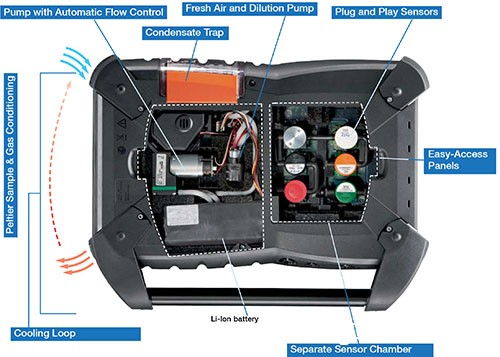

3. ANALYZER BOX – INDUSTRIAL STANDARD, ROBUST AND RELIABLE

The advantages of the analyzer box

Special chambers offer comprehensive protection for the sensors and electronics from dust and deposits

4. EASILY ACCESSIBLE SERVICE OPENING

Access to all relevant service and wearing parts such as pumps and filters, which can then be quickly cleaned and/or exchanged on site.

The advantages:

- Reduction of instrument unavailability due to service times.

- Cost savings due to instrument maintenance and/or exchange and cleaning of wearing parts by the user.

- Immediate access to all relevant wearing parts

5. THERMALLY SEPARATED SENSOR CHAMBER

The sensor chamber is thermally separated from the other instrument components. This reduces possible sensor drifts caused by thermal influences. This allows the maximum reliability pf the measuring instrument to be achieved.

6. EASY EXCHANGE OF THE GAS SENSORS

The gas sensors are pre-calibrated and can be exchanged, replaced or extended by further measurement parameters without test gas – if necessary directly at the measurement site.

- No more long service times

- Flexible extension of the testo 350 by further gas measurement parameters when applications or regulations change.

- A report is immediately issued when the NO sensor filter is used up. Then only the filter needs to be changed, and no longer the whole NO sensor

7. AUTOMATICALLY MONITORED CONDENSATE TRAP

The automatic monitoring of filling level reports when the condensate container needs to be emptied, and a few minutes after the report, the measurement gas pump is automatically stopped. This provides the highest protection of the analyzer box and the gas sensors from damage by condensate entry.

8. EXTERNAL COOLING LOOP

Closed cooling loops isolate the instrument electronics and sensors from the ambient air. The interior of the instrument is cooled via a heat exchanger and therefore does not come into contact with dirty or aggressive ambient air.

- Damage to the internal electronics are thus effectively prevented.

- The instrument can also be safely used in dusty or dirty atmospheres

Further advantages... Diagnosis function – integrated and intelligent The testo 350 has a number of instrument diagnosis functions. Error reports are issued in clear text, and are thus easily understandable. The current status of the flue gas analyzer is constantly displayed. This guarantees:

- Low downtimes thanks to early warning reports, for example when gas sensors are spent.

- No false measurements due to faulty instrument components.

- Better planning of measurement work

- More reliability in emission measurement and up-to-date information on the instrument status.

Automatic zeroing of the pressure sensor

This option allows volume nad mass flow velocity to be measured without supervision over a longer period of time and parallel to the emission measurement. The pressure sensor is automatically zeroed at regular intervals. This avoids the typical drift of the pressure sensor when ambient conditions change.